What Is DTF Printing and How Does It Work?

DTF (direct-to-film) has exploded because it’s flexible, durable, and fast to deploy. Instead of spraying ink straight onto fabric, you print to a coated PET film, add an adhesive powder, cure, and heat-press the design onto garments. The result is crisp color and strong wash resistance on cotton, polyester, blends, nylon, and more. In this guide, I’ll walk through the workflow, answer common questions, and compare DTF to DTG, screen printing, and sublimation—so you can choose the right method with confidence.

What Is DTF Printing and How Does It Work? The Short Version

DTF prints your artwork to PET film with water-based CMYK + white inks. While the ink is still wet, you apply a hot-melt adhesive powder and cure it. Then you heat-press the film to the garment, peel the film (often hot peel), and post-press for durability. That’s it—no pre-treat required, and color stays vibrant even on dark fabrics.

What Is DTF Printing and How Does It Work? Step-by-Step

-

Print to film: CMYK artwork first, then a solid white underbase.

-

Powder and cure: Apply adhesive powder evenly; cure with a press (no-contact) or small oven.

-

Pre-press garment: Quick press to flatten and dehumidify.

-

Transfer: Press film to fabric ~15–20 seconds at ~165 °C.

-

Peel and post-press: Peel the film (hot peel is common) and post-press to lock in durability.

Pro Tips for Smooth Transfers

-

Keep films, inks, and powder in spec; humidity swings cause headaches.

-

Store finished transfers flat; avoid dust contamination on adhesive areas.

-

Test pressure and temperature per fabric—nylon often needs shorter, cooler presses.

What Is DTF Printing and How Does It Work? Pros and Cons

Pros: Broad fabric compatibility, vivid color and fine detail, no pre-treat, excellent wash resistance, and great economics for short-runs or one-offs.

Cons: Requires dedicated inks/films/powder and routine maintenance; hand feel is slightly firmer than DTG on lightweight tees; uses PET film and adhesive, which add material waste.

DTF vs. DTG vs. Screen Printing at a Glance

| Method | Best For | Notes |

|---|---|---|

| DTF | Mixed fabrics, darks, short-runs | No pre-treat; vibrant detail; slight hand feel |

| DTG | Cotton tees, photo prints | Softest hand feel; pre-treat needed |

| Screen | Bulk orders, simple art | Lowest unit cost at scale; setup per color |

Which Is Better DTF or Sublimation?

It depends on products. Sublimation infuses dye into polyester for a soft, all-over feel and unmatched breathability—amazing for performance wear and hard goods with poly coatings (mugs, mousepads). DTF covers the surface with an adhesive-bonded ink layer, so it shines when you need color on cotton, blends, nylon, or when you’re mixing fabrics in one catalog. If your line is mostly polyester and you want full-bleed coverage, sublimation wins. If you need versatility across fabrics and colors with low setup, DTF takes it.

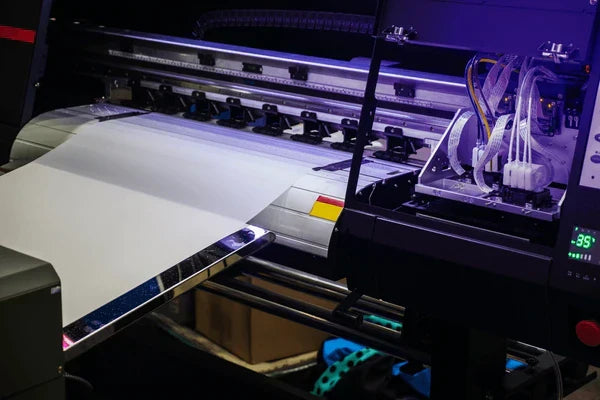

What Printer Is Used for DTF?

True DTF setups include a printer with CMYK + White channels, DTF-compatible heads, a reliable media path for PET film, and RIP software that controls white underbase, ink limits, and drop sizes. In production, many shops add an automatic powder shaker and curing unit for consistency. Entry configurations can be compact, but uptime depends on maintenance (white ink circulation, regular head cleanings, humidity control).

Can I Turn a Normal Printer into a DTF Printer?

You can modify certain printers, but it’s not plug-and-play. You’ll need DTF inks, PET film handling, a workable path for thicker media, a white-ink solution, and RIP software. Even then, reliability hinges on daily care—especially with white ink. For consistent commercial output, dedicated DTF hardware is usually the safer long-term bet. If you’re testing the waters, start with a reliable small DTF system or partner with a transfer supplier.

Can You Print DTF Transfers on a Regular Printer?

A regular office inkjet or laser won’t work. DTF relies on pigment inks formulated for textiles, a white underbase, and film + powder + heat chemistry to bond to fabric. Without those, transfers will fail or wash out. Stick to DTF-capable machines and the proper consumables.

File Prep and Color Tips for Clean Results

Use transparent-background PDFs or PNGs at 300 DPI for crisp edges. Avoid semi-transparencies and feathered fades; they often look grainy at the transfer edge. Work in sRGB IEC61966-2.1 for predictability, and remember that ultra-neon hues will be mapped to the nearest printable color. When in doubt, build a color swatch and run a quick test press before launching a large run.

Durability, Feel, and Care

A well-made DTF transfer resists cracking and peeling through dozens of washes. The hand is smooth but slightly firmer than an ultra-soft DTG print on ringspun cotton. To maximize life, advise customers to wash garments inside-out, cold, and tumble low or hang dry. Post-pressing (and proper pressure) pays dividends in both edge seal and long-term feel.

When DTF Makes Business Sense

DTF excels when you need on-demand variety across multiple fabrics, frequent color changes, and short turnaround with low setup. It’s perfect for micro-drops, local events, and small-batch brand testing. If you’re scaling a single, simple design into thousands of units, screen printing still crushes unit cost. Many modern shops run a hybrid: DTF for prototypes and niche SKUs, screen for stable, high-volume winners.

Practical Resources, Repairs, and Deeper Reads

For hands-on maintenance and decision guidance, see What is DTF Printing and Why Are So Many Print Shops Switching?. It covers common issues (like white-ink clogging), cure tips, and cost considerations in plain language. If you’re comparing methods, an accessible overview of related tech is Direct-to-garment printing for background on pre-treatment, inksets, and surface chemistry.

Quick Notes on Operations and Add-Ons

Keep a tight humidity window to protect heads and prevent static on films. Standardize cure time/temperature/pressure per fabric family and document it—operators will thank you. For brand polish, build inside-neck labels as separate transfers and post-press briefly to seat them. Little touches compound into a premium unboxing moment.

Related Products You Might Be Exploring

If you’re mapping out your supply chain or looking to fine‑tune your production workflow, it helps to know where to find the essentials. Explore DTF Supplies, MUTOH ECO INKS, MIMAKI INKS, and Mutoh Inks for a snapshot of the inks and consumables that underpin high‑quality transfers. Keeping these products on your radar can inspire improvements in print quality, sustainability and efficiency, especially as you expand into new fabrics and finishes.

Key Takeaways

-

DTF is fabric-flexible, detail-friendly, and pre-treat-free.

-

It beats DTG on fabric range and setup speed, and beats screen on short-run economics.

-

Sublimation remains king for polyester and full-bleed, ultra-soft results.

-

Success comes from consistent curing, clean files, and disciplined maintenance.