What Makes DTF Different from DTG (Direct-to-Garment) Printing?

When it comes to textile printing, the options can feel overwhelming. DTF (Direct-to-Film) and DTG (Direct-to-Garment) printing are two prominent methods, but they serve vastly different purposes. So, how do you decide which one is right for your needs? Let’s dive into the nitty-gritty to clarify what sets these technologies apart.

Understanding the Basics of DTF and DTG

DTF Printing: The Versatile Contender

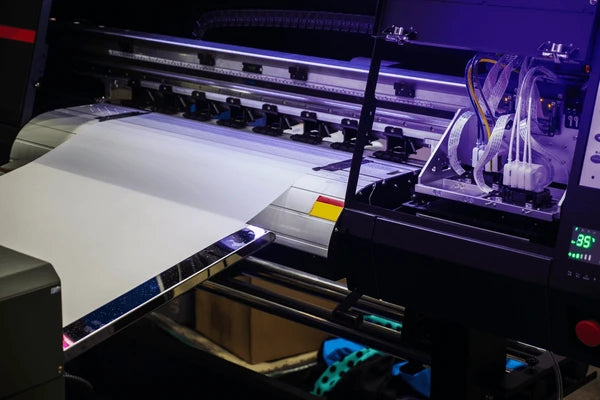

DTF (Direct-to-Film) printing involves printing designs onto specialized DTF transfer film and then transferring those designs onto a substrate (usually fabric) using heat and pressure. This process is versatile, accommodating materials like cotton, polyester, blends, and even non-fabric surfaces.

One of the biggest draws of DTF is its ability to adhere to nearly any surface. Whether it’s a t-shirt, a tote bag, or even wood, this technology delivers durability and high-quality prints. Plus, DTF ink bottles offer vibrant colors and sharp details, making designs pop.

DTG Printing: A Direct Approach

On the other hand, DTG (Direct-to-Garment) printing is more specialized. It directly prints onto textiles, primarily cotton or cotton blends. This method relies on water-based inks that are absorbed by the fibers, producing soft, seamless prints.

DTG excels in producing photorealistic designs with intricate details but is best suited for cotton-rich fabrics. Unlike DTF, it struggles with non-fabric materials or synthetic blends.

Key Differences Between DTF and DTG

Materials and Application Flexibility

DTF shines in its compatibility with multiple surfaces. Whether it’s cotton, polyester, leather, or even plastic, DTF film delivers. DTG, while excellent for fabric fidelity, falters when asked to go beyond textiles.

Ink and Color Management

DTG inks are water-based and designed specifically for fabric absorption. While this leads to incredible softness, it limits application. Meanwhile, DTF leverages DTF ink bottles, which are specially formulated for transfer and adherence, ensuring vibrant results across surfaces.

Cost and Scalability

DTG printing is best for short runs or one-off designs due to setup and material costs. DTF, with its broader application, is more cost-effective for diverse product runs, making it ideal for businesses catering to custom orders.

Durability and Maintenance

DTF prints excel in durability. Designs can withstand washing, stretching, and wear over time. While DTG also offers excellent longevity, its performance heavily depends on fabric type and post-treatment processes.