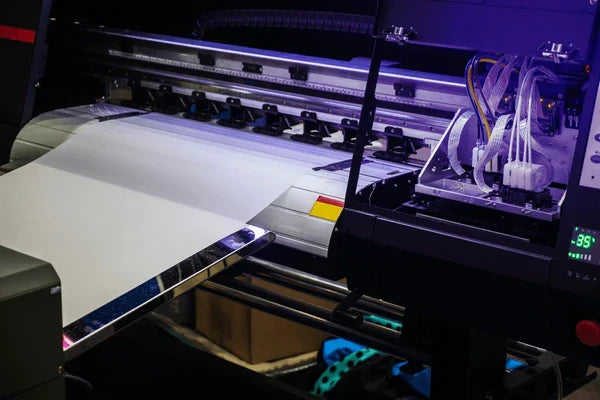

Direct‑to‑Film printing has quickly become a favorite among garment decorators because the transfers are vibrant, stretchy and easy to apply. I’ve been amazed at how flexible a well‑made DTF print feels when it’s pressed onto a T‑shirt. Because of that flexibility, people often ask Does DTF crack easily? The short answer is no – cracking isn’t inherent to the technology. Cracks appear when something goes wrong during production or care, such as using poor materials or pressing at the wrong temperature. In this article I’ll walk you through why DTF prints are so durable, what causes them to crack, and how you can maximize their lifespan.

Understanding DTF Print Durability

DTF transfers bond ink and adhesive powder directly to fabric fibers. When properly applied, this bond is flexible and designed to stretch with the garment. Industry tests show that a high‑quality transfer can endure 50–100 washes before noticeable degradation, which rivals or exceeds traditional methods like screen printing or vinyl. The ink layer itself also resists fading; the colors remain vibrant even after many wash cycles. This combination of flexibility and colorfastness is why DTF is now used for workwear, sports jerseys and fashion apparel alike. However, that durability depends on following best practices throughout the printing and pressing workflow.

How to keep DTF from cracking?

Cracking almost always points to a process error rather than a flaw in the technology. Based on my experience and industry guidance, there are several steps you can take to keep your transfers smooth and flexible:

-

Use high‑quality materials. Cheap PET film or ink can become brittle under heat. Premium products like DTF Inks and DTF Supplies are formulated to withstand heat and mechanical stress.

-

Calibrate your heat press. A heat press that runs too hot or too cold can ruin a transfer. Keep the temperature within 320–350 °F (160–175 °C) and apply medium pressure as recommended for your film. Too little heat leaves the adhesive inactive; too much can over‑activate it and make the print brittle.

-

Fully cure the adhesive powder. Before pressing onto fabric, cure the powder so it melts and bonds to the ink without over‑baking. Under‑curing leaves the powder chalky, causing weak adhesion; over‑curing makes the transfer stiff and more prone to cracks.

-

Pre‑press garments. Moisture or wrinkles trapped in the fabric disrupt adhesion. Pre‑pressing removes humidity and smooths the surface, ensuring even contact.

-

Test and adjust. Every heat press behaves a little differently. Run a few test prints on the same fabric to fine‑tune your settings and avoid surprises during production.

-

Store supplies properly. Keep film, powder and ink in a cool, dry place. Old or expired materials lose bonding strength and can lead to cracking.

When you follow these steps, DTF prints remain supple and crack‑free for the life of the garment.

Importance of Correct Heat Press Settings

Temperature and pressure play critical roles in DTF. The adhesive on the film activates at specific temperatures. If you press too low, the adhesive never fully melts and the design peels off; if you press too high, it over‑activates and the ink layer becomes brittle. Medium pressure ensures full contact between film and fabric; insufficient pressure causes incomplete bonding while excessive force can crush the ink and scorch the cloth. For most fabrics I recommend:

-

Temperature: 320–350 °F (160–175 °C)

-

Pressure: Medium, typically 40–60 psi

-

Time: 10–15 seconds, followed by a second press for a few seconds with parchment or Teflon paper to fully cure

Monitoring your press with an infrared thermometer and pressure gauge can help maintain consistency. Remember to adjust the settings for special fabrics like nylon or spandex; these substrates may require lower heat or shorter press times to prevent scorching.

Fabric Selection and Material Quality

Not all fabrics behave the same during heat application. Smooth cotton and polyester blends offer the most consistent results. Highly textured fabrics, ribbed knitwear or coated polyester can prevent proper adhesion. Stretchy materials like spandex may pull the design apart unless you use flexible adhesive powders or add stretch additives. In those situations, choose specially formulated films and inks that move with the fabric. High‑quality consumables – such as Digital Printing Inks – ensure a strong bond and maintain color vibrancy. Avoid expired supplies; inks and films have a shelf life and degraded components can cause peeling or cracking.

Care Practices for Longevity

Even the best transfer can fail if the garment isn’t cared for properly. To maximize lifespan:

-

Wait before washing. Allow the print to cool and cure for at least 24 hours after pressing.

-

Wash inside out. Turn garments inside out to minimize friction on the print.

-

Use cold water and mild detergent. Hot water and harsh detergents can break down the adhesive and ink.

-

Avoid bleach and fabric softeners. Chemical agents weaken the bond and can cause the design to flake.

-

Air dry or use low heat. High dryer temperatures accelerate degradation. Air drying is best; if you must use a dryer, select a low‑heat setting.

-

Iron with care. Never iron directly on the print. Place a Teflon sheet between the iron and the garment or iron inside out at a low temperature.

These simple habits complement good production practices and significantly extend the life of your DTF garments.

Does DTF crack or peel?

Under normal wear and proper washing, DTF prints should not crack or peel. The technology produces a flexible ink layer that moves with the fabric, and the adhesive powder creates a strong bond with the fibers. When cracks appear soon after printing, they almost always indicate one of the following:

-

Incorrect curing: Adhesive powder that’s under‑cured remains chalky and doesn’t bond; over‑cured powder becomes brittle and snaps.

-

Poor film or ink quality: Low‑grade materials shrink or warp under heat.

-

Moisture or contaminants: Humidity trapped in the film or fabric interferes with bonding and leads to surface cracks.

-

Improper heat press settings: Too little pressure leaves gaps in adhesion; too much pressure squeezes out adhesive and weakens the design.

By identifying the root cause, you can quickly correct the process. Re‑pressing a faulty transfer with proper temperature and pressure may salvage it; if the materials are at fault, replace them with better DTF Supplies.

How long will a DTF print last?

When applied correctly and cared for properly, DTF prints often outlast the garment itself. Lab tests and industry data suggest that a well‑applied transfer can withstand 50–100 wash cycles. Some fabrics, like thick hoodies or sweatpants, may show wear around forty washes because the bulky material traps heat and moisture. On tote bags or cotton tees, the design may look great after sixty washes or more. Compared to screen printing (40–50 washes), direct‑to‑garment printing (25–40 washes) or heat‑transfer vinyl (20–30 washes), DTF generally lasts longer. Sublimation can exceed one hundred washes but is limited to polyester; DTF offers similar longevity across a wider range of fabrics.

Durability comparison

| Method | Durability (wash cycles) | Comments |

|---|---|---|

| DTF printing | 50–100+ | Flexible; works on many fabrics |

| Screen printing | 40–50 | Can crack if ink isn’t cured |

| Heat‑transfer vinyl (HTV) | 20–30 | Often peels or cracks over time |

| Direct‑to‑garment (DTG) | 25–40 | Best on cotton; may fade |

| Dye sublimation | 100+ | Extremely durable but only on polyester |

This table, drawn from multiple sources, shows why DTF is now a preferred option for small businesses and hobbyists alike.

What are the disadvantages of DTF?

While DTF offers impressive durability and color range, it isn’t perfect. The process involves several steps: printing on film, applying adhesive powder, curing, then pressing onto the garment. This is more time‑consuming than direct‑to‑garment printing and requires specialized equipment. Upfront costs for a quality printer, heat press and consumables can be higher than vinyl cutting. Poorly applied transfers may have a rubbery feel on lightweight fabrics, and learning the correct settings takes practice. Additionally, some users find that high‑temperature curing emits fumes; ensure your workspace is well‑ventilated. For certain projects, screen printing or sublimation may still be a better fit.

Despite these downsides, I believe the versatility and longevity of DTF make the learning curve worthwhile. Investing in reliable DTF Inks and DTF Supplies helps minimize defects and produce a softer feel. If you’re curious about the basics of the process, check out the repair guide article What is DTF Printing and How Does It Work? for a step‑by‑step overview.

Troubleshooting and Repairing Cracked Prints

Even seasoned printers occasionally encounter cracking. When you see lines forming across a design or edges lifting, take a systematic approach:

-

Inspect the crack pattern. Random cracks across the design suggest heat or pressure issues, while consistent cracks in specific areas may point to fabric incompatibility or bad film.

-

Check press settings. Use a thermometer and pressure gauge to verify actual temperature and pressure. Adjust up or down gradually and run tests until the transfer adheres smoothly.

-

Consider material quality. If you used generic film or expired ink, replace them with premium supplies. High‑quality films and powders melt evenly and remain flexible.

-

Re‑press with protective layers. Sometimes a second press with parchment or Teflon can bond the print more firmly and eliminate small cracks.

-

Switch fabrics or adhesives. For highly elastic garments, use stretch powders or choose fabrics with less spandex. Test on similar fabric before large runs.

If cracks persist after following these steps, you may need to start over with new film or adjust your artwork. It’s better to remake a few prints than deliver flawed products to customers.

A final word on DTF durability

So, does DTF crack easily? Not when it’s done right. The technology itself is robust and flexible. Cracking and peeling arise from poor materials, incorrect heat press settings, inadequate curing or mishandling. By investing in quality equipment and DTF Supplies, calibrating your process, and advising customers on care, you can produce transfers that stay vibrant and crack‑free wash after wash. As someone who has pressed countless garments, I’ve seen DTF prints endure daily wear for years. With a little attention to detail, your designs can too.