What is the Purpose of a DTF Auto Powder Shaker?

In the dynamic realm of textile printing, efficiency and precision are paramount. Did you know that integrating an Automatic TPU Adhesive Powder Shaker into your Direct-to-Film (DTF) printing workflow can significantly enhance both? Let's delve into the purpose and benefits of this essential equipment.

Understanding DTF Printing

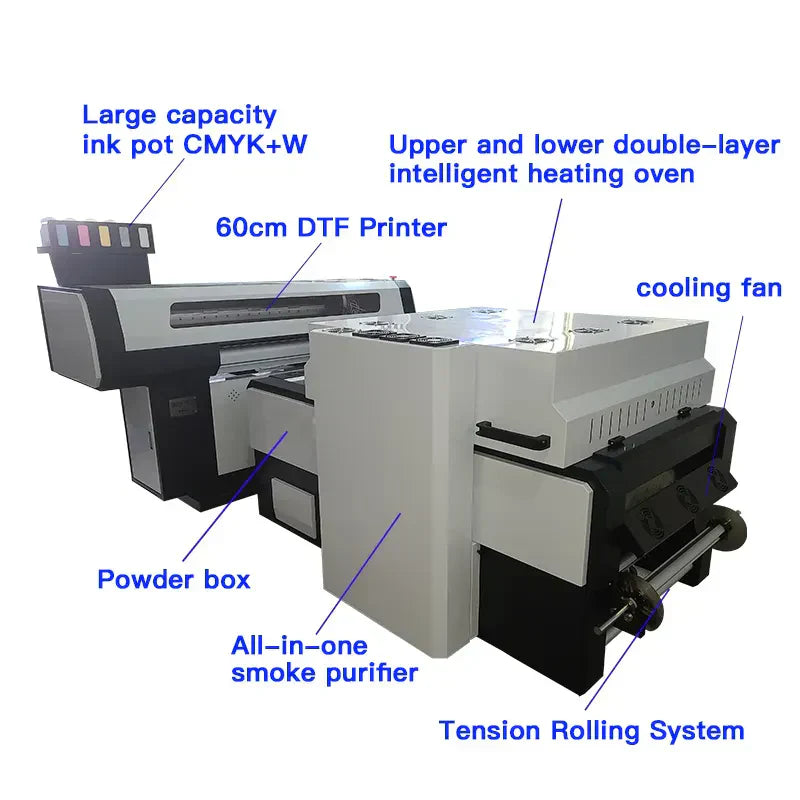

Direct-to-Film (DTF) printing is a revolutionary method that enables high-quality prints on various fabrics. Unlike traditional techniques, DTF printing involves:

- Design Printing: The design is printed onto a specialized PET (Polyethylene Terephthalate) film using a DTF printer.

- Adhesive Application: A layer of adhesive powder is applied to the printed film.

- Curing Process: The adhesive-coated film is heated to cure the powder, ensuring it adheres properly.

- Transfer to Fabric: The cured film is placed onto the fabric, and heat is applied to transfer the design.

This process results in vibrant, durable prints suitable for a wide range of materials, including cotton, polyester, denim, leather, and nylon.

The Role of the DTF Auto Powder Shaker

What is a DTF Auto Powder Shaker?

A DTF Auto Powder Shaker is a specialized machine designed to automate the application and curing of adhesive powder in the DTF printing process. By integrating this equipment, you can achieve:

- Consistent Powder Application: Ensures even coverage of adhesive powder across the printed design.

- Efficient Curing: Reduces production time by streamlining the curing process.

- Minimized Manual Intervention: Decreases the likelihood of human error, leading to higher quality outputs.

Why is it Essential?

Manual application of adhesive powder can lead to inconsistencies, affecting the quality and durability of the print. An Automatic TPU Adhesive Powder Shaker addresses these challenges by:

- Ensuring Uniform Powder Distribution: Crucial for strong adhesion and longevity of the print.

- Reducing Waste: Precise application means less excess powder, leading to cost savings.

- Enhancing Productivity: Allows for continuous operation without manual bottlenecks, increasing overall efficiency.

Benefits of Using a DTF Printer with Shaker

Improved Print Quality

Incorporating a DTF Printer with Shaker ensures that each print receives the optimal amount of adhesive powder, resulting in:

- Sharper Details: The powder adheres precisely to the printed areas, maintaining intricate design elements.

- Vibrant Colors: Proper curing preserves the brightness and accuracy of colors.

- Increased Durability: Prints withstand washing and wear, maintaining their quality over time.

Streamlined Workflow

Automation simplifies the DTF printing process by:

- Reducing Manual Steps: Frees up time for operators to focus on other tasks, improving overall workflow.

- Decreasing Likelihood of Errors: Consistent, automated processes lead to fewer mistakes and reworks.

- Allowing for Scalability: Easily ramp up production to meet increased demand without proportional increases in labor.

Cost Savings

While there's an initial investment, the long-term benefits include:

- Lower Labor Costs: Automation reduces the need for manual labor, leading to savings.

- Decreased Material Waste: Precise powder application minimizes excess use of materials.

- Higher Throughput: Increased production capacity leads to greater profitability.

Integrating CadLink Software for Optimal Results

To maximize the potential of your DTF Auto Powder Shaker, integrating it with CadLink software is advisable. CadLink offers:

- Advanced RIP (Raster Image Processing) Capabilities: Ensures accurate color reproduction and print quality.

- Seamless Workflow Integration: Efficiently manages print jobs from design to final output.

-

Customization Options: Tailor settings to meet the specific needs of different projects, enhancing versatility.

By combining CadLink with your DTF setup, you can achieve superior control and quality in your printing operations.

Conclusion

Incorporating a DTF Auto Powder Shaker into your printing workflow is a strategic move that enhances quality, efficiency, and profitability. By automating critical steps and integrating advanced software like CadLink, you position your business at the forefront of textile printing innovation.

For a deeper understanding of DTF printing and its applications, consider exploring this comprehensive guide: DTF Printing: A Comprehensive Guide.